With over 20 years' experience covering the complete spectrum of engineering applications, we are experts in vehicle development. It is therefore essential for us to keep an eye not only on the big picture, but also on the all-important details. From concept development to series launch support of individual parts and modules and the development of complete vehicles - we combine expert knowledge with the latest lightweight construction material technology trends. For you, this means an optimum implementation of your vehicle concepts, both technically and economically. From the module to the complete vehicle, with EDAG your engineering challenge is in good hands.

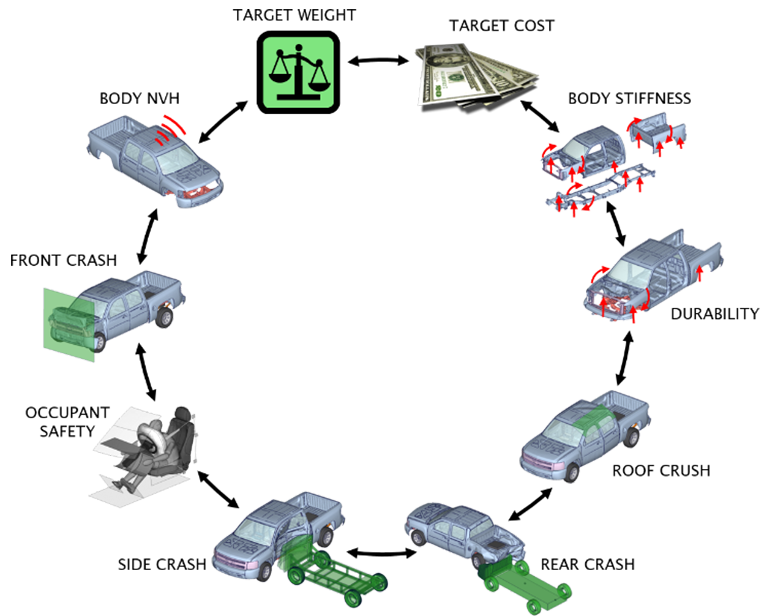

"Integral safety" is the coordinated interaction of active and passive safety requirements, and therefore compliance with the relevant safety requirements, including certification. For us, it means even more: our vehicle safety experts are already involved during the concept phase. A great advantage, as most of the modifications made to the vehicle's structure and interior components at this stage influence the deformation characteristics of the car in the event of a crash.

In turn, the front end package and design of its body in white and exterior parts influence the achievement of objectives in pedestrian protection and, to some extent, in passenger safety, too.

It is also, for instance, possible to use sensor data from active safety systems such as distance control or braking assistants etc. to pre-condition systems for passive safety or to activate them earlier.

The added value to you: greater safety for your customers and smooth, uncomplicated approval and homologation procedures.

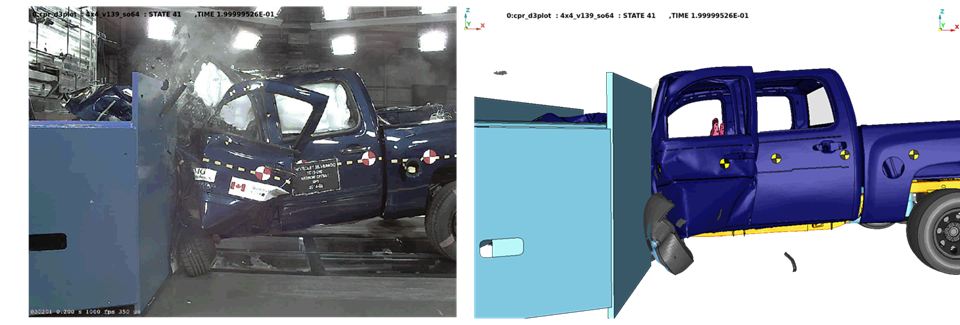

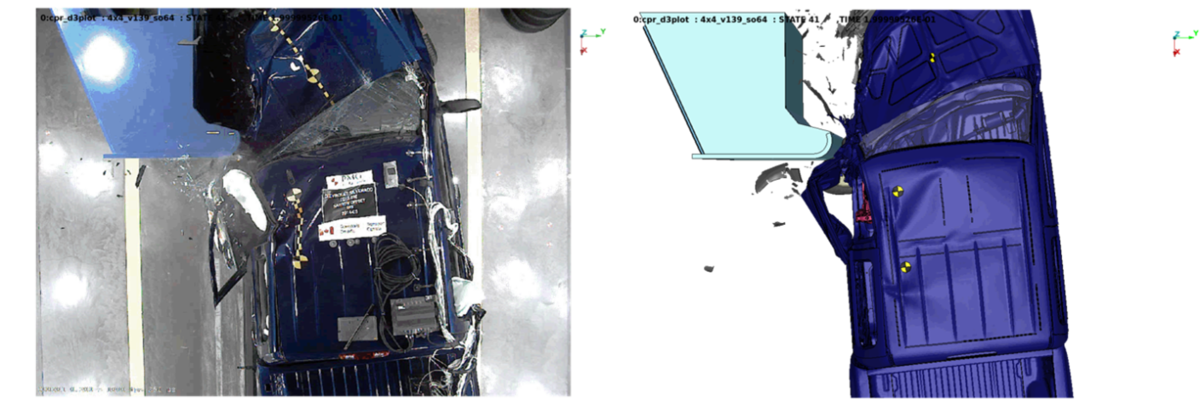

EDAG’s experience in simulation will support your total vehicle development in all the specialties needed to meet your customers’ requirements. For example, we are the only commercial supplier of CAE simulation under contract for the National Highway Traffic Safety Administration in developing new crash safety regulations and consumer testing. By validating products and product properties at an early stage, development periods are shortened, development costs reduced, and last but not least products improved.

The key factors here are virtual simulation and testing within the framework of computer-aided engineering (CAE), because whatever can be simulated while the concept is still in its initial stages will not need to be constructed at a later date - a process which is both complex and expensive.

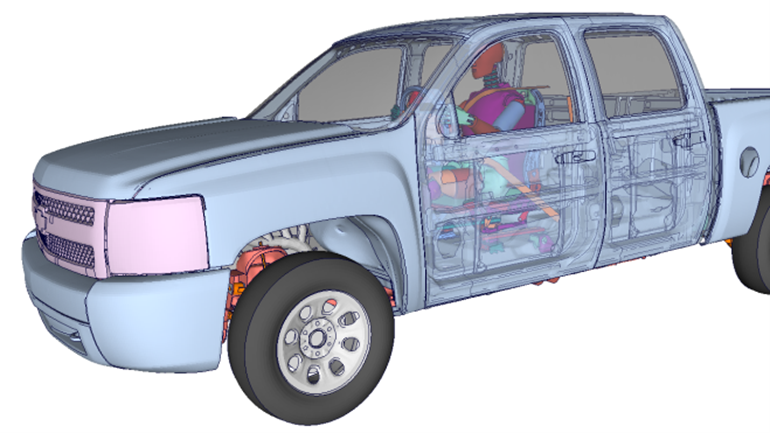

Our CAE experts support production development with the functional design of components, systems and complete vehicles. By applying virtual simulation and calculation, we are able to optimize the stresses of components, in this way reducing weight, to test various material concepts (e.g. steel, plastic, aluminum, GRP, CFRP) in intelligent networks with our test laboratories, and to carry out different load situations, including vehicle crashes. And if the existing software tools are unable to cover the desired application, we have a solution for that, too – our software team programs tools for customers' specific applications, to optimize in-house process times and generate new solutions.

We offer the following solutions and services to meet your needs:

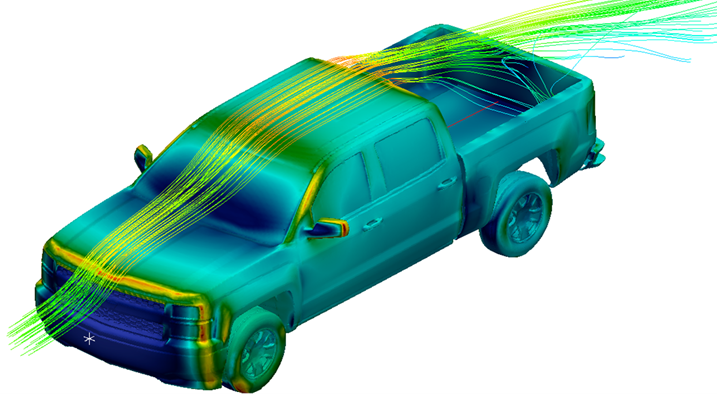

The point of aerodynamics is to make it possible for a vehicle to travel against the wind with as little air resistance as possible. This is enormously important, as experts see aerodynamic optimization - along with many other improvements relating to weight and engine efficiency - as an effective way of reducing fuel consumption. Expert knowledge is required here, as it is important to analyze the effects on vehicle handling, but also, for instance, on pedestrian protection. The latter sometimes conflicts with vehicle superstructures, which are becoming flatter and more streamlined.

As a supplier of solutions, we have an Aerodynamics department to develop your vehicles so that they are less affected by aerodynamic forces. All while the various requirements of today's automobiles are still met inside and out.

In addition, we have also developed special knowledge and competencies in the aeroacoustics field for convertibles with soft tops and RHT roof systems, engine compartment air flow, thermal management, underbody dynamics, brake cooling and ways of improving vehicle dust and dirt management.

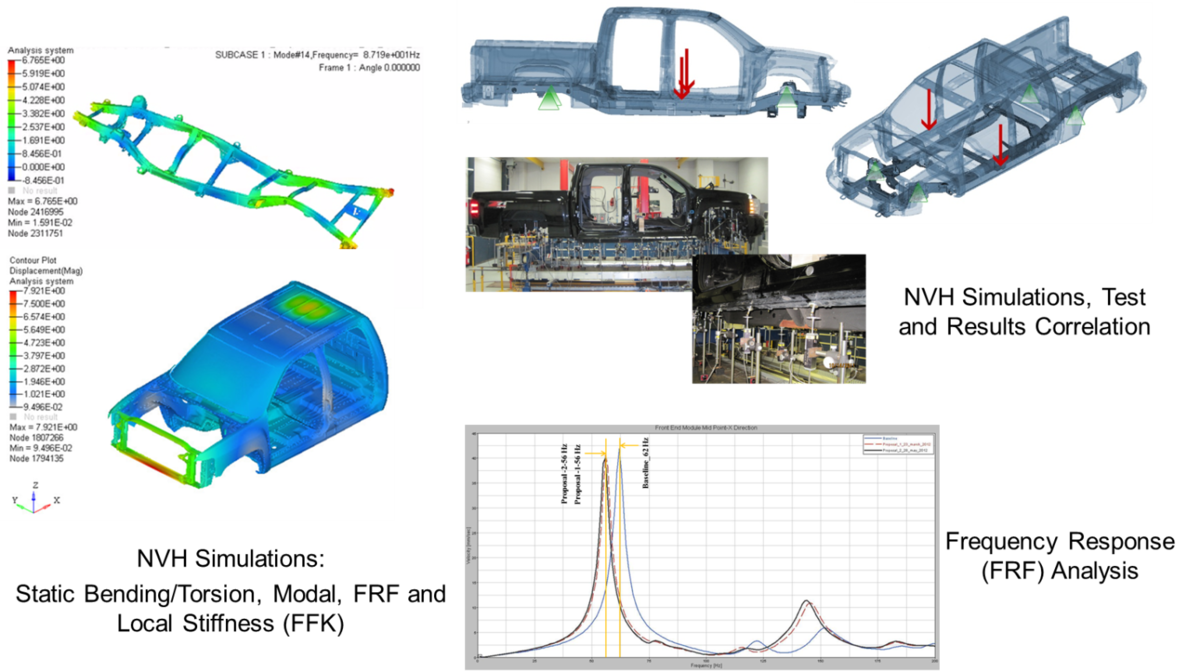

Acoustics and comfort play a decisive role in the driving experience in modern vehicles. Only if the car is as noise-free as possible and delivers maximum vibration and driving comfort, will the car make a lasting impression on the customer.

We attach a great deal of importance to a pleasant driving experience, and are therefore working on the acoustic and vibration-related qualities of modern cars. Our aim is to consciously design the vehicle's sounds in line with vehicle character and the overall concept. An aim that meets the requirements of discerning automobile customers.

We offer the following solutions and services to meet your needs:

* MSC.NASTRAN is proprietary software of MSC Software

CDH.AMLS is proprietary software of CDH AG

nCode DesignLife is proprietary software of HBM Testing and Measurement

Abaqus is proprietary software of Dassault Systems

See our international website for more information.